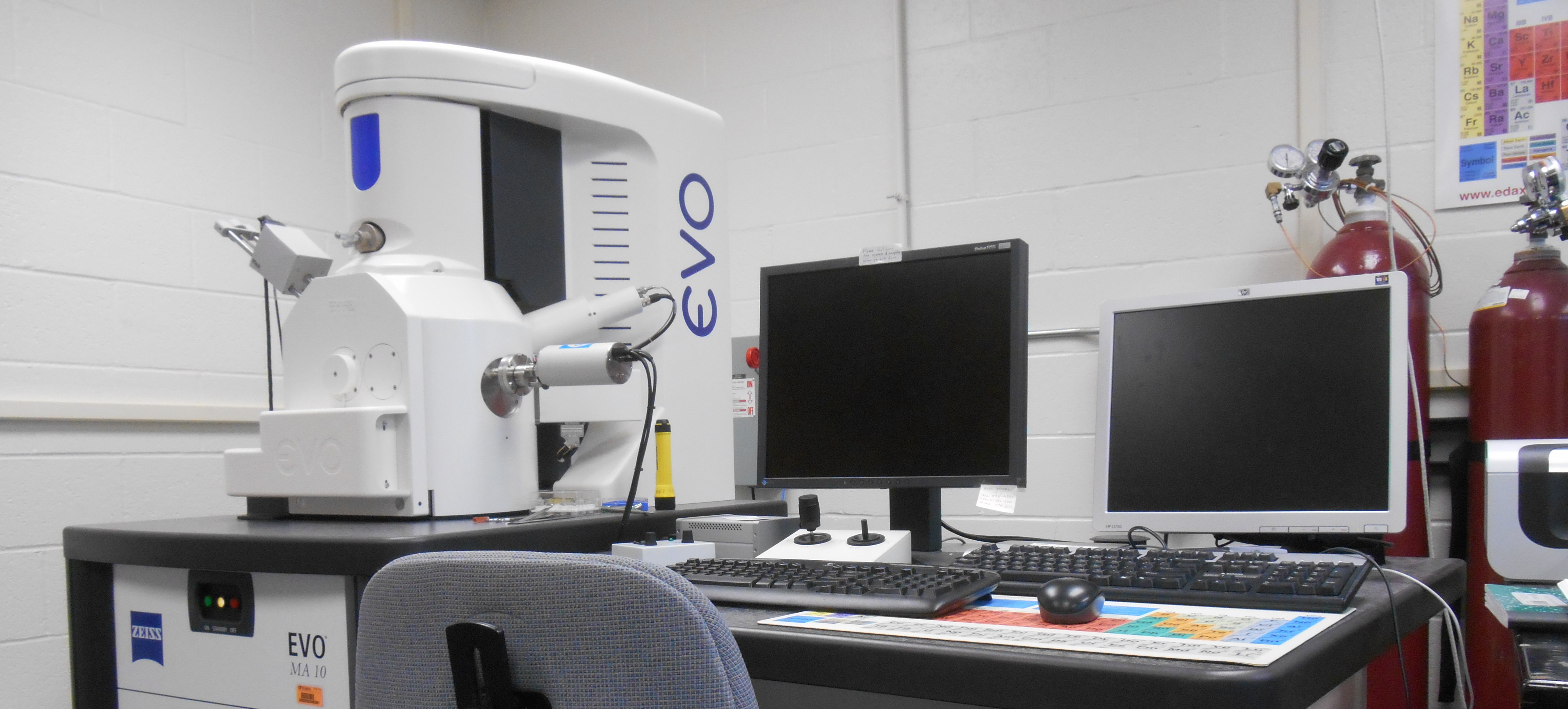

The Scanning Electron Microscope (SEM) is an important tool for imaging material surface as well as for identifying chemical signatures. The UF Department of Geological Sciences has an SEM laboratory equipped with a Zeiss EVO MA10 and an EDAX EDS spectrometer. This instrument has variable pressure capability, allowing imaging and analysis of non-conductive surfaces without the need for carbon-coating in most situations.

Detectors

- The present SEM system is equipped with following detectors for diverse applications:

- Secondary Electron Detector (SED)

- Variable Pressure Secondary Electron Detector (VPSED)

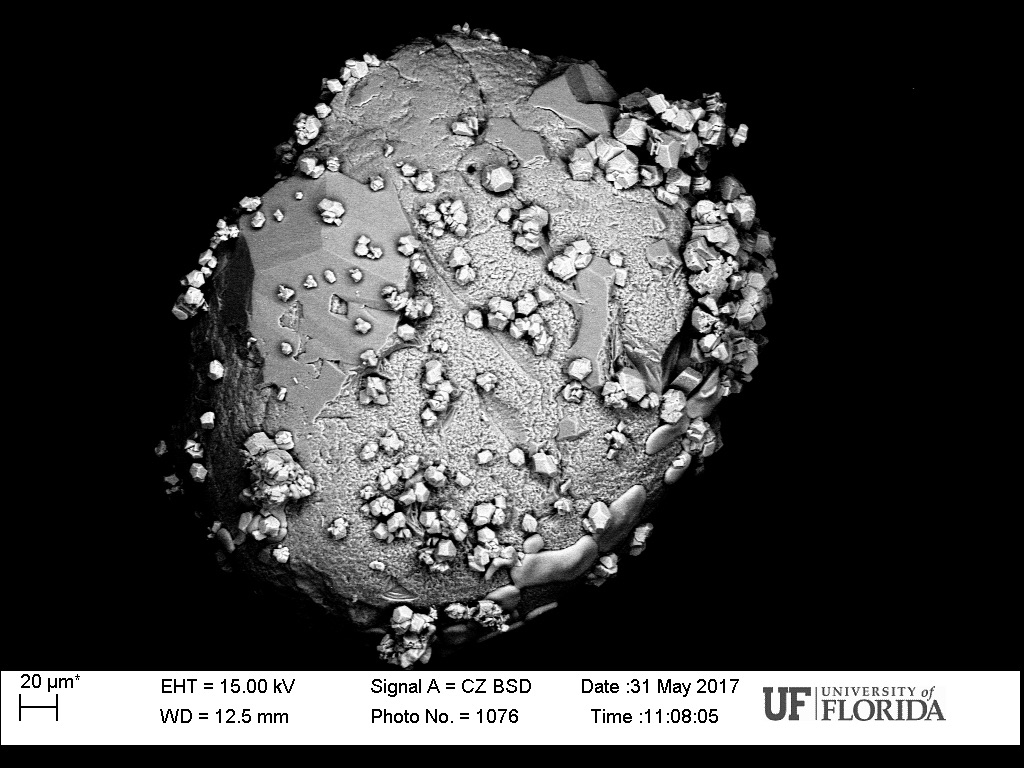

- Backscattered Electron Detector (BSD)

- Energy Dispersive X-ray Spectrometer (EDS or EDX: “GENESIS XM2” manufactured by EDAX)

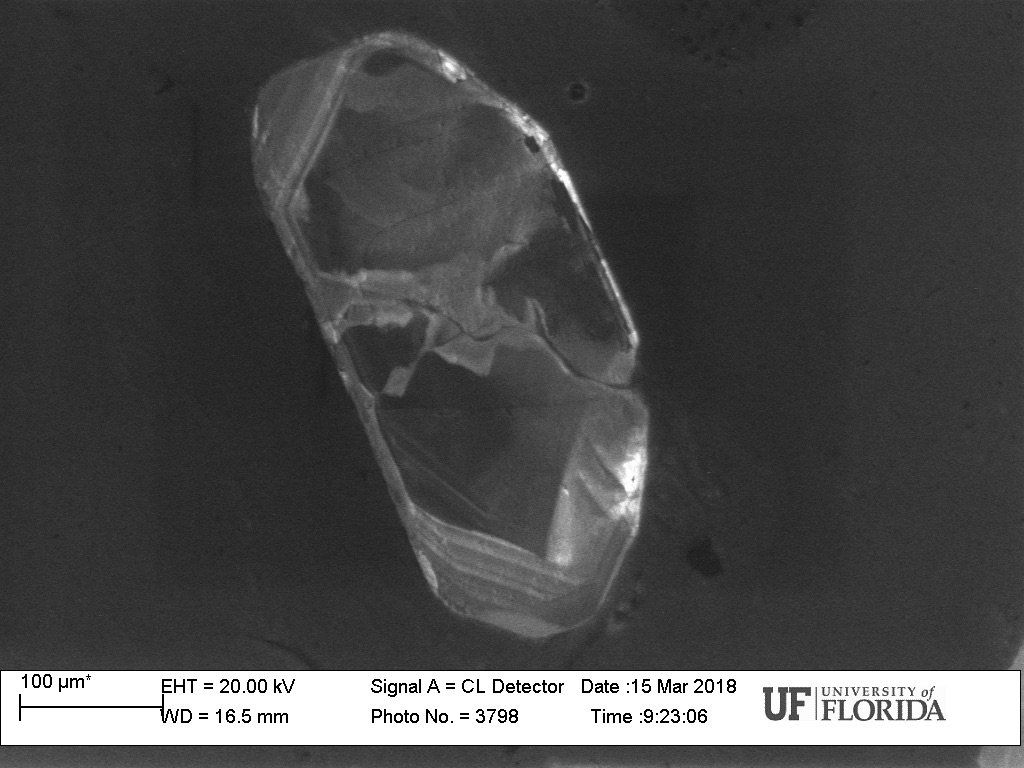

- Cathodoluminescence detector (CLD: “MiniCL” manufactured by Gatan)

Targets and Sample Preparation

The targets can be almost any type of solid materials having resistance to an incident electron beam (<30 kV). Common examples are metal, rock, soil, glass, plastic, polymer, fiber, ceramic, concrete, biological entities, or any combination of these.

The MA10 introduces a controlled amount of air to the chamber in variable pressure mode. Interacting with secondary electrons, the introduced molecules become ionized, efficiently neutralizing charges (electrons) accumulating on the sample surface. Because of this capability, the MA10 can generate a stable signal for non-conductive specimens, eliminating the need for coating with conductive substances. This capability allows for users to perform SE/CL imaging and EDS analysis with least chemical contamination of the target – this aspect is important for some applications which require multiple experiments on a single specimen with minimal interference. If, however, coating is desired for your applications, a carbon coater (Denton Sputter Coater Desk IV) is available in the lab.

SEM Laboratory Analysis Prices

| Charges are on a per hour basis. | |

|---|---|

| Department Member (or collaborating researcher) | $15 |

| UF Other Departments | $30 |

| Other Academic Institution (not collaborating) | $60 |

| Commercial Entity | $120 |

Please contact the Lab Manager Dr. Dogancan Yasar for further information.